Life As A Surfer

The Environmental Impact of Surfing: Part Two – Surfboards

Carbon footprinting is the process of understanding the greenhouse gases and environmental impact created from the manufacturing of a product. It is measured from its birth to disposal or ‘Cradle to Grave’. This process can be applied to surfboards by understanding the production and life cycle of a surfboard.

Carbon footprinting is the process of understanding the greenhouse gases and environmental impact created from the manufacturing of a product. It is measured from its birth to disposal or ‘Cradle to Grave’. This process can be applied to surfboards by understanding the production and life cycle of a surfboard.

The Life of a Surfboard

i) Extraction of raw materials

The oil used to make the resin and fins needs to be drilled out of the earth and wood for the stringer has to be grown and harvested

ii) Processing

Turning the oil into plastic requires energy and other resources. The wood needs to be debarked and cut into strips for the stringer or rails which requires energy

iii) Manufacture

iii) Manufacture

Once the constituent chemicals have been made the foams can be manufactured with requires even more energy and consumables

iv) Transportation

Between each stage the raw materials, processed chemicals or manufactured products have to be transported creating carbon

v) Shaping

Once each constituent part has reached the shaper more energy and consumables are used to make the finished surfboard

vi) Repair & Maintenance

During its life a surfboard becomes damaged and needs repairing and fin plugs replacing, or new fins purchased which creates a further carbon impact

vii) Disposal

Most surfers keep a surfboard for as long as possible but eventually the surfboard can no longer be used so has to be recycle for another purpose, e.g. wall art in a bar or goes to landfill

Most surfers keep a surfboard for as long as possible but eventually the surfboard can no longer be used so has to be recycle for another purpose, e.g. wall art in a bar or goes to landfill

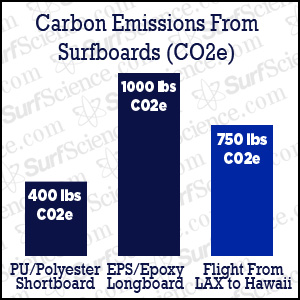

The annual production of new surfboards, roughly 750,000, creates around 220,000Tons of CO2e. (In my eyes this is too much!) For example an average Polyester resin Shortboard around 6’1 has the carbon footprint of around 400lbs CO2e and an epoxy 9’1 Longboard is around 1,000 lbs CO2e. Compare this with a flight from LAX to Honolulu Hawaii which would produce about 750lbs C02e.

The trend for surfers to go green has become evident in boardies & wetties. Surfers are demanding environmentally friendly products. Because of this, many companies claim their products are green, but they never advertise an exact carbon footprint value. This makes it difficult for consumers to compare their options.

For example an epoxy surfboard has a larger carbon footprint than a polyester based resin surfboard of the same shape. Many surfers believe an epoxy surfboard will last longer, so it is more environmentally friendly in the long run, but there are a lot of variables to account for.

Fortunately, there are some ways that shapers and surfers can reduce the carbon footprints of surfboards.

Surfers

1) Order a sturdy board, make sure it has enough layers of fibreglass to support your weight and the type of wave you surf, a 4oz top and bottom makes a relatively weak surfboard.

1) Order a sturdy board, make sure it has enough layers of fibreglass to support your weight and the type of wave you surf, a 4oz top and bottom makes a relatively weak surfboard.

2) Add in more fin plugs, go for 5 fins making your board adaptable to different waves rather than having two. Even with Longboards try a 4 + 1, loads more fun!

3) If a board gets dinged repair it ASAP, so less damage can occur

4) Buy and trade second-hand surfboards reducing the number of unused board. For every board that gets ridden instead of sitting unused, one less new board will have to be made.

5) Surf your board untill it is completely unrideable as a surfboard then turn it into something else. You can try snow/dune surfing or practice your repairs on it. There will be someone out there who wants it! Some people are even turning old boards into art like Amanda from RESURFACE.

6) You can also consider carbon offsetting your surfboard. To do this, you reduce your carbon impact in another area of your life to help make up for the impact of your surfboard. One way you can do this is by riding your bike to work a few days a month.

Shapers

1) Use deck channels to strengthen your surfboards so they last longer

2) Use sustainable alternatives like plant based resins, recycled foams and bio-plastic based fin plugs. By using a plant based polyester resin shapers could save up to 73,000 Tons of CO2/year

3) Use renewable on site energy production, like solar panels and wind turbines. You will save money on your energy bill plus, when its blown out, you'll have some consolation in the fact that you're generating clean energy with your wind turbines.

Conclusion

Reducing the carbon impact of your surfboard is actually pretty easy, but it takes both shapers and surfers to make a positive environmental change. If we all work together, we can reduce the carbon impact of surfing and set an example for other sports.

Rick Lomax BSc Hons and AIEMA

During his Surf Science degree Rick started looking at the carbon footprint of surfboards and compared the performance of sustainable plant based surfboards to traditional materials. He has since developed the Surfboard Carbon CalculatorTM and launched Decarbonated Consultancy a company on a mission to make the extreme sports industry environmentally sound. He has presented his expert knowledge on Bio-based surfboards and Surfboard Life Cycle Analysisat the InCrops; Bio-Sports conference 2010 and the Regional Studies Association SW Annual conference 2010.

1 Comment